PV Grid-connected Combiner Box

Product Overview

The photovoltaic grid-connected junction box combines the DC inputs of up to 24 photovoltaic cell components in series into one or multiple outputs, with each output equipped with fuses, lightning arresters, and circuit breakers. This simplifies the input wiring of DC distribution cabinets and inverters, providing protection against lightning, short circuits, and grounding. The junction box is available in two types: intelligent and non-intelligent. The intelligent lightning protection junction box has a current monitoring unit in its interior that can monitor the current input of each photovoltaic cell series and the total output voltage, as well as the temperature inside the box, the status of the lightning arrester, and the status of the circuit breaker.

The internal layout of the device is simple and clear, with neat and reasonable wiring. The device has high reliability and is easy to maintain. It can be installed outdoors on a wall, and can adapt to various harsh environments. In addition to the relevant core components, others can be customized according to user requirements.

Product features

★The protection grade of the combiner box reaches IP65, and it is equipped with waterproof, dustproof, rustproof, and salt spray proof functions, meeting the requirements for outdoor installation:

★It can simultaneously connect up to 24 battery strings:

★Each positive and negative pole of the battery series in each path is equipped with a photovoltaic dedicated fuse to protect the components series from faults. The fuse base and fuse are paired for use, reducing the maintenance cost of the owner and effectively protecting the personal safety of maintenance personnel:

★By using photovoltaic dedicated high-voltage surge protectors, the positive and negative terminals of the busbar after convergence can be protected against ground, and the continuous working voltage (Uc) can reach 1000VDC:

★The power module in the combiner box can connect to a maximum photovoltaic voltage of 1000DCV:

★The control module of the combiner box adopts reliable Honeywell Hall elements (DC CT sensors) to collect data on the current and bus voltage of each photovoltaic string, monitor and locate alarms and local faults, and measure the temperature inside the combiner box, as well as detect the status of lightning protection devices and output circuit breakers etc:

★It has RS485/MODBUS-RTU serial communication capability:

★There is lightning protection for all external interface parts:

★It can receive parameter downloads from local monitoring devices for analysis and processing:

★The working power supply of the junction box can be selected from the external 220VAC/DC or the power supply provided by the junction box itself. If the power supply provided by the junction box itself is used, there is no need for separate wiring for power supply at the site:

Technical parameter

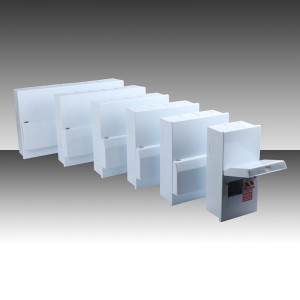

| Product model | BWX-PV24 | BWX-PV16 | BWX-PV12 | BWX-PV8 |

| Number of input channels | 17-24 | 13-16 | 8-12 | 8 |

| Maximum input voltage | 1000Vdc | |||

| Each input current | 0 -20a | |||

| Maximum output current | 250A | 160A/200A | 100A/125A/160A | 100A |

| Input waterproof terminal size | PG9/PG11/MC4 | |||

| Output waterproof terminal size | PG21-PG32 | PG19-PG25 | PG16-PG21 | PG135-PG19 |

| Monitoring module | 、、、、()Detect each current, bus voltage, circuit breaker status, mold protector status, and box temperature (optional) | |||

| /Communication method/protocol | RS485 /MODBUS-RTU RS485 bus/standard MODBUS-RTU protocol | |||

| Anti reaction function | ()Configure modular packaging anti reflection diodes (optional) | |||

| Temperature and humidity | :-40°C~+85°C ,95%,、Working temperature: -40°C~+85 °C, humidity of 95%, non condensing, non corrosive gas environment | |||

| altitude | ≤4000m | |||

| Monitoring module power consumption | ≤8W≤ 8W during operation | |||

| Auxiliary power supply | :AC85V-265V/DC24V(±10%)/DC200V- 1000VAuxiliary power supply:AC85V-265V/DC24V(±10%)/DC200V- 1000V | |||

| Cabinet material | //Hot dip galvanized steel plate/stainless steel/cold rolled steel plate | |||

| Protection level | IP65 | |||